News

-

MAE 298 SEMINAR: Technology Developments for FIR Bolometric Detector Focal Plane Assemblies

-

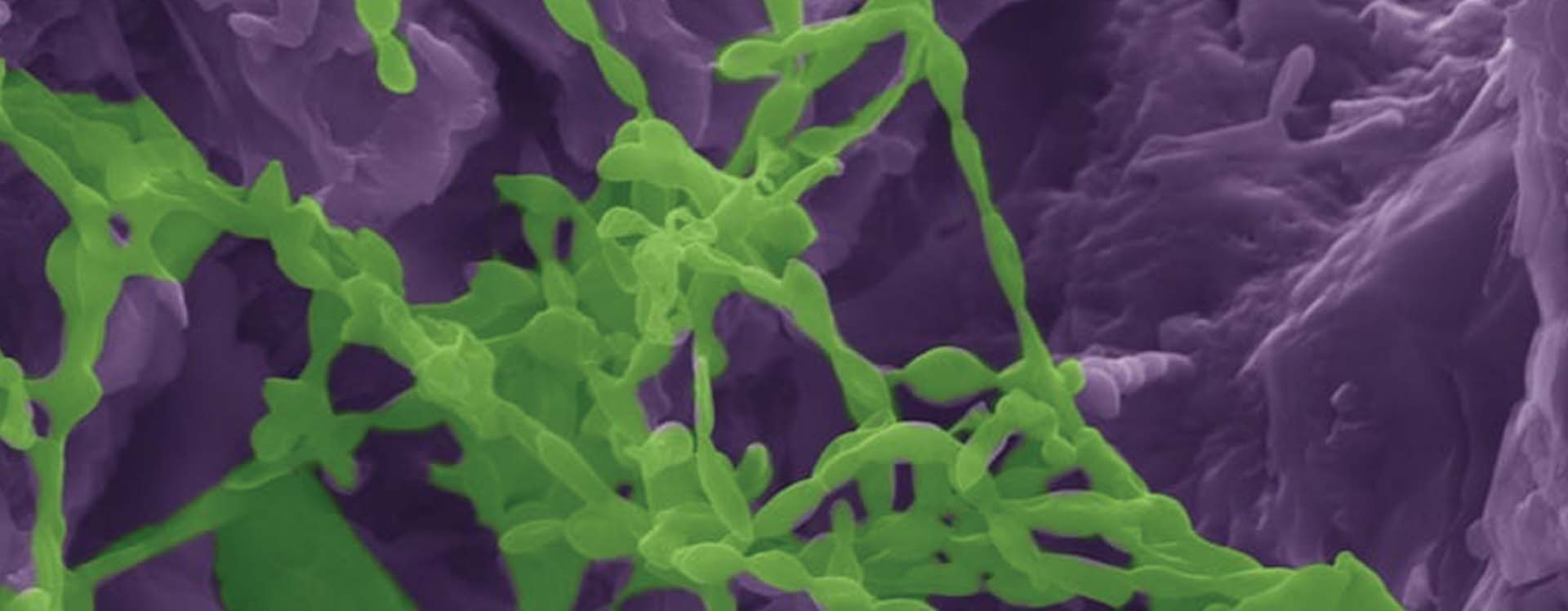

CBE 298 Seminar: The Wisdom of the Crowd: Watching Bacterial Collectives (Re)shape Themselves

-

CEE Seminar: BIM and the Digital Twin

-

MSE Special Seminar: Revolutionizing Battery Technology - Engineering Quantum Materials for Enhanced Safety and Performance in Solid Electrolytes

-

MSE Special Seminar: Designing Sustainable Soft Matter from the Molecule Up